So, what’s different with the new car? A commonly asked question, HM20203 is very similar to my first car, HM1078. So why and what?

Why?

Everyone talks about the concept of “if I had it to do over again, what would you . . .” There were few if any things I changed due to this concept. Yes, I did learn some tricks after building the first one, but for the most part, HM2023 is a totally different approach. Maybe the biggest motivator, ‘I like to build’. I just completed an almost three-year project and have a number of years of ‘annual upgrades’ ahead of me. I can play with the new one and still have time for other activities.

What’s different?

As I started HM2023, I wanted to be even more period-correct in the build. I had learned and experienced a number of items over the past ten years. If you are exposed to enough originals, you accumulate a lot of data and files. (More on that at the end)

This is a list of items that were incorporated into HM2023. I’ve splashed a few photos thru this page, to make it more appealing, visually. You can click on each of the titles to go to a page dedicated to that particular feature with a ton more photos on each.

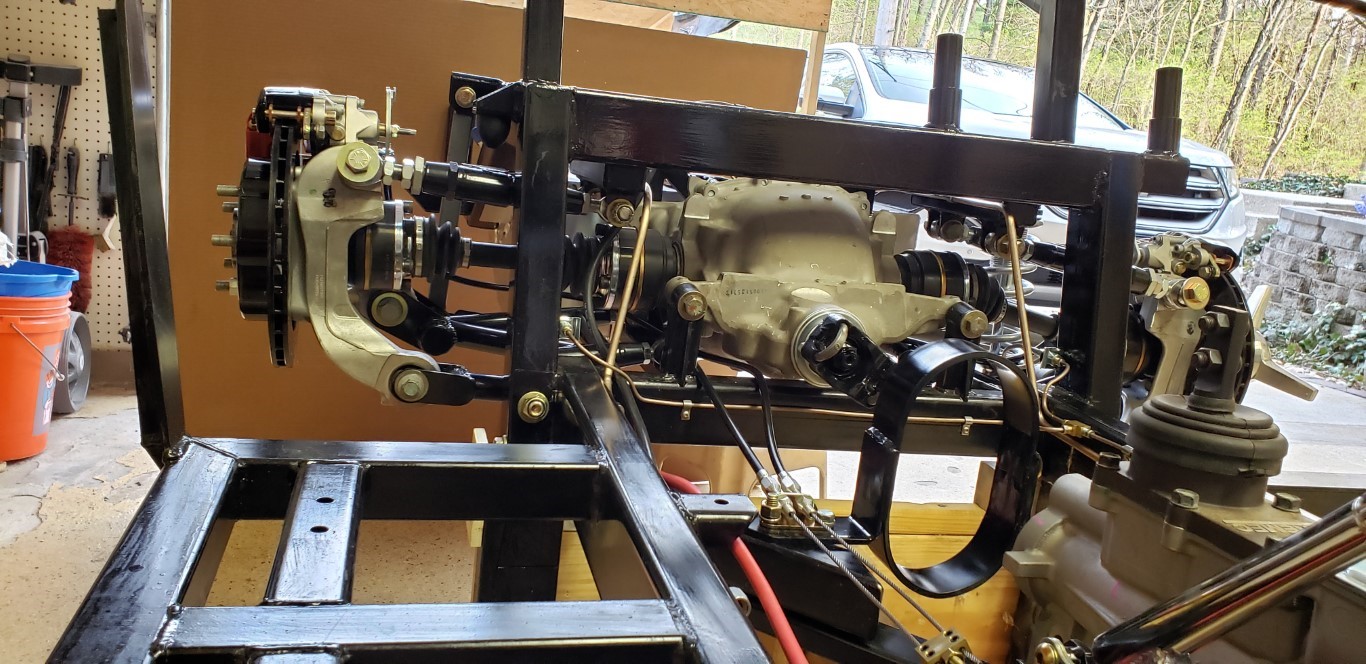

- S550 based IRS: Ford Performance discontinued the production of the T-Bird IRS

components which forced a redesign of the IRS used in most replica builds. Mine was the first build by Hurricane using this system.

components which forced a redesign of the IRS used in most replica builds. Mine was the first build by Hurricane using this system. - Differential yoke: The S550 differential uses a ‘Guibo’ style driveshaft coupling which makes for a complicated connection with adapters between the driveshaft and differential. I’ve found a differential yoke that eliminates all this.

- eBrake: The older Ford-based emergency brakes were less than optimal. They worked best on a hill if you put a rock under the tire after you set the e-brake. Being period-correct with 15″ wheels, I developed a way to add a secondary set of calipers to lock the rear wheels with the eBrake lever – and it works.

- Fuel Tank: My work with the tank on the previous build converted it from plastic to aluminum tank and then tapered the tank to make it less visible from the rear. That tank was extremely heavy and only had a 12-gallon capacity. It severely limited your cruise range, especially with a big block. I developed a new aluminum tank to use the available space in the rear of the car with access to the mechanics from a hatch in the trunk. The new tank incorporates a Stealth 340 submersed pump, Centroid fuel sensor, baffling, rear edge tapered to hide it under the rear of the car, removable and provides 18-gallon capacity.

- Trunk Latch: Two changes here, concealing the latch mechanism inside the trunk lid and adding a bracket to the rear of the frame to accept a proper latch.

- Rear taillights: The Hurricane body was splashed off a 3200+ series original, which has a formed flat surface to accept two round taillights. Yet they supply the rectangular style lights used on the 3000-3199 series cars. I modified the shape around the taillights to match the early models and properly mount the rectangular light

- Trunk Aluminum: The Hurricane design has a very generous trunk capacity. I chose to line all flat surfaces with sheet aluminum to make them appear more realistic.

- Tank Filler: As part of the tank redesign, I moved the filler slightly to gain more trunk space.

- Rear Battery: I’ve had luck with the smaller AGM style batteries so I incorporated a built-in retaining system, again to increase trunk capacity.

- Rollbar strut: The junction of the rollbar strut and frame was a little ‘unfinished. I built a cosmetic bracket to finish this part/area.

- Wheel Openings: The fiberglass body came with a flat flange which made the edge of the wheel opening. Original cars incorporated rolled aluminum around a piece of wire to form a reinforced, smooth edge. I reshaped the edge on all four corners to replicate this edge. How many times have you been to a car show when someone comes up and feels this edge to see if the body is fiberglass or aluminum?

- Cockpit corner/rear-wheel opening: The originals incorporate a molded corner in the cockpit to fair the sides to the rear bulkhead. The Hurricane design includes a door latch support piece in this area that sticks into the wheel well, with no finishing or fairing. I spent some time adding foam and fiberglass to make this blend in a little better.

List getting long? Hold on, we’ve just begun!

Cockpit edge: The original aluminum bodies wrapped the aluminum skin around a 3/4″ tube to form the opening of the cockpit. I replicated this in all edges of the cockpit. At the front, the originals had a piece of the birdcage tube that poked thru the dash – included in my build.

Soft-top bow brackets: The soft-top of the car requires a tube bracket above the driver. Sockets to mount this are located near the driver and passenger’s shoulder, just behind the door, inside the cockpit. My mod not only included the brackets and chrome sockets but necessitated adding a support bar from the rear cowl brace to the door latch bracket.

Door latch brackets: I added a formed steel bracket that bolts into the cockpit tub/support frame to emulate the original style bracket.

SideScreen sockets: The soft-top uses side screens for windows. These include a pin that fits into a socket on the doors. This required not only drilling holes for the sockets but also forming a socket near the rear latch.

Transmission tunnel: The Hurricane design incorporates a fiberglass tub to form the cockpit, including the drivetrain tunnel. You can pull and change a transmission or clutch with this, but it isn’t the easiest. I like the original and ERA design where the tunnel is removable. I cut out most of the fiberglass tunnel and replaced it with a formed aluminum piece. It adds a lot of work and isn’t noticeable (except for the more accurate shape at the front) but if I ever need to replace the transmission, . . .

Dash: Lots of changes here. I started with a formed aluminum dash, using a street-car layout. Mostly because I included a glove box and the S/C & Comp series didn’t have a glovebox. I learned how to hammer-form aluminum. Covered with black vinyl.

Gauges & switches: Smiths gauges in all locations as well as Lucas switches.

Interior details: Notice the ashtray and Impact branded harness. Again, attention to detail is what gains points with the judges and especially your cobra peers. How many replicas include the cigarette lighter on the dash? The cabinet pull on the glovebox?

Creature comforts: These were not included with the original cars, they were pretty rough although the originals have foot box vents and a heater/defroster setup. I chose to include a heater/defroster, which complicates the glovebox configuration. I added bilge blowers to the foot box vents. Heated seats. We also incorporate a ‘lap blanket’ which mounts to the dash to capture heat within the cockpit when cruising in colder weather. This really increases your comfort level and is highly recommended.

Seating: I chose to recover the vinyl seats with leather. What a difference in feel. The seats were also raked back an additional 7°. Each seat is equipped with a slider and the period-correct Leveroll knob.

Cup Holders: I am really averse to looking at a well-done replica and there on the transmission tunnel are a couple cup holders! You got to be kidding – there weren’t cup holders in 1965! Yet we all know how we’ve become accustomed to them and how handy they are. Look close, I’ve incorporated a couple hidden holders at the rear of the tunnel.

Brake Bias: I have tracked my cars and setting brake bias for that or setting it for everyday use is not easy. I just added the bias adjuster so I can easily change it on the fly. Not used much but it really makes initial brake set-up much easier.

Floor Mats: Just a little touch to finish it off. The Cobra logo on a floor mat is only available from one vendor and not for our cars. I found a way to get it done.

Door sills: The Hurricane build doesn’t help much here and this needs attention for a finished appearance. I found an aluminum molding that accomplishes this.

Rearview Mirrors: Learned from the first one, the dash-mounted mirror should not be on center and the fender-mounted one is not optimal. Go for a windshield mount.

Badging: In addition to the standard 427 and cobra badges, I’ve added the windshield and radiator badges commonly found on an original. Again, the details.

Pedals: The Hurricane Gen II cars now come with floor-mounted pedals. But it still takes some work to get them to look as they should. The ‘loud pedal’ is my own design, copying the originals

Cowl Support Tubes: this is the first originality mod most guys do. I’ve learned to make them removable for service, make the attachment hardware ‘retained’ so you don’t need three hands to put it in. The speedometer cable runs thru the right tube.

Glovebox: I replicated the hinging and rolled edge/piping of the originals. Had to modify my internal box to clear the heater and defroster ducting.

We’re almost done, now the stuff on the front, the details everyone always wants to see!

Hood frame & skin: The originals incorporate an aluminum skin over a 3/4″ tube frame. Check √ Really proud of this mod. I used the outer skin of the Hurricane hood and attached it to the frame I built. Thanks for your help, Alec. This mod allowed me to include the original style hood latches and trim plates.

Hood frame & skin: The originals incorporate an aluminum skin over a 3/4″ tube frame. Check √ Really proud of this mod. I used the outer skin of the Hurricane hood and attached it to the frame I built. Thanks for your help, Alec. This mod allowed me to include the original style hood latches and trim plates.

Firewall: Many changes here. I began by replacing the upper area and angling it to match the original builds. Then covered in aluminum and the original electrical items added for visual accuracy.

Hood Latch: This mod incorporates the original style latch levers, handles, skin bezels and formed angle anchors welded to the birdcage.

Footbox: The GenII cars include an angled top foot box, but it is a couple inches too high which makes it difficult to install the wiper and vents, along with making it difficult to access the engine and sparkplugs. A fair amount of work but it makes a big difference. I used the original corrugated heat shield on the side of the boxes. The top is white fiberglass, again period-correct.

Birdcage tubes: The originals include a square support tube that runs from the cowl to the front upright. Adding these complicated the headers but it must be part of the package.

Slip-joint headers: Sorry, the originals didn’t have a flange plate welded to the header tubes, this was an idea that came from Factory Five (Ouch, bad word). A little more work but I prefer the original slip-joint style

Exhaust exit: The exhaust tubes exit thru an opening cut into the body side, closed on all four sides.

Heat-shield: The floor-mounted pedals put the master cylinders close to the headers and the issue of heat. I built a stainless steel heat shield between the two.

Fluid reservoirs: As on the originals, three Girling styles reservoirs with hard piping to the master cylinders.

Wiper motor: Mounted on the drivers side footbox, I found the original Lucas 3DR style motor and mounting. This connects to the RH park wipers and blades

Mechanical Linkage: Spent a little time fabricating the levers and brackets to match what ole’ Phil Remington did on the originals. I am using a Borla ITB system which requires a very accurate/positive linkage system to perform at its best.

Voltage Regulator & Solenoid: Items from the ’60s, still available today. Details, details.

Footbox Vents: Period-correct vent valves, knobs, hoses, clamps and ducting. The only deviation was to add blower fans to increase the airflow when stopped.

Overflow tank, radiator & hoses: I prefer to use a dual-pass radiator to help with the cooling. This puts the radiator inlet tube on the driver’s side, like the originals. I modified the FE overflow tank to gain more hood clearance and added the bleeder tube on the passenger side. The top of the radiator includes the formed tank and Serck labeling as the originals.

Hooters: (love that English terminology) Lucas 9H horns and bracketry.

Remote oil filter: This not only looks correct, you need to do it to get an oil filter on the big block.

Oil Cooler: The original 13row unit, modified to include a drain plug for easier oil changes and a stainless steel rub plate to protect the finish.

Pusher fans: The originals had an over-heat issue. Remington grabbed a couple Falcon fan motors and a couple HVAC blades and fabricated an impromptu cooling system. We’ve learned the puller fans work better but you need these for the correct look. They do add some cooling help but not as much as you’d think. The pullers are really efficient.

Hood and scoop riveting: A mod most do, mine is actually functional, it helps bond the skin to the tube frame.

Pin-Drive wheels: Yes, I stuck with the 15″ size.